Why do I need upgraded brakes?

A lot of the performance upgrades we talk about will do to your car make it faster. It’s easy to understand why you want those. Things that slow your car down, perhaps not so much. It’s just not as exciting as tuning for speed, or handling. It’s still very worthwhile though.

Look at it this way – driving on the road, day to day, you spend a lot of time speeding up and then slowing down again. The more speed you can call upon, on when it is safe and opportune to do so, the more speed you’re going to have to take off in time for the next corner, traffic light, or queue of traffic.

Similarly, a car with upgraded handling is going to place greater demands on your brakes just because you’re likely to carry more speed through well sighted corners. We’ve found that small light cars with upgraded suspension need to upgrade their brake set-ups to ones that will take significant amounts of heat.

There’s also the cool factor, of course. Nothing shouts “performance” like a set of big brake callipers or upgraded brake discs behind your wheels. If you’re running a set of relatively open wheels, you get to enjoy the visuals as well as the stopping power.

We’re going to talk you through some of the brake upgrades available to you.

Pads

You can do a lot with just a brake pad upgrade. For a relatively small outlay, you can upgrade your cars braking system with an upgraded compound brake pad and feel real improvements almost straight away.

When we talk about brake pads, we tend to talk about compounds. This is what the pad is made of. There’s a wide range of manufacturers and compounds on offer, and everyone has their personal favourite. Perhaps the biggest difference between these compounds is what temperature range the pad is intended to work in.

On a track car, the brakes get a vigorous, sustained workout and stay at least warm most of the time. They’re also likely to be hitting much higher temperatures than those on your road car. On the road generally brake pads have much easier lives. They do get chance to cool down, and there is no warm-up lap before you start driving. This means the pad must work from cold, and probably won’t get as hot (you’d hope).

This means that you tend to be able to choose from a spread of compounds that work well from cold, but perhaps can’t cope with those higher temperatures through to compounds that can take the sustained punishment of an endurance race but wouldn’t stop your car effectively on a frosty December morning, and everything in between.

There are many compounds which work well enough from cold and will give you an increased upper working temperature. It’s just important to bear in mind that you need that balance.

A good indication that a pad is going to work well when cold is if it carries ECE R90 certification. This means that the pad performs similarly to the original pads on the car under testing. Not every popular road pad does carry this, but it is a legal requirement in many countries.

There’s also disc wear to consider. Some of the higher performing compounds will wear your brake discs quicker, which may be something to consider on a commuter car you are putting plenty of miles on.

Exactly where on this scale you land is going to depend a bit on what you drive and how. Lighter cars and more moderate driving styles need less aggressive pads than heavier cars and harder driving.

If you just need pads that perform exactly as the originals did, you can’t go far wrong with Brembo or EBC’s range of OE pad compounds. These tend to be designed to perform almost exactly as the pads that came with your car did.

Then we have mild upgrades, like EBC’s Green Stuff compound. Pads like this are designed to offer better than stock stopping power, but not at the expense of cold performance or disc wear.

Their Yellowstuff compound is further along the scale. This is a high-performance compound designed to be used on both track and road. It works well from cold but gets better as the pad gets hot. Many of these pads carry R90 certification. Where only get better as the pad gets hotter though.

The Bluestuff NDX compound is the latest in the ‘Stuff line up. It’s another high performance brake pad for entry level track day and fast road use. It is stable at higher rotor temps than Yellow Stuff and has longer life too. The majority of Blue Stuff pads have R90 certification.

Further along the scale again would be something like Ferodo’s DS2500 compound. Ferodo actually consider this to be a track compound, but it is persistently popular on some tuner cars. It doesn’t carry ECE R90 certification, so it may not be road legal in some countries.

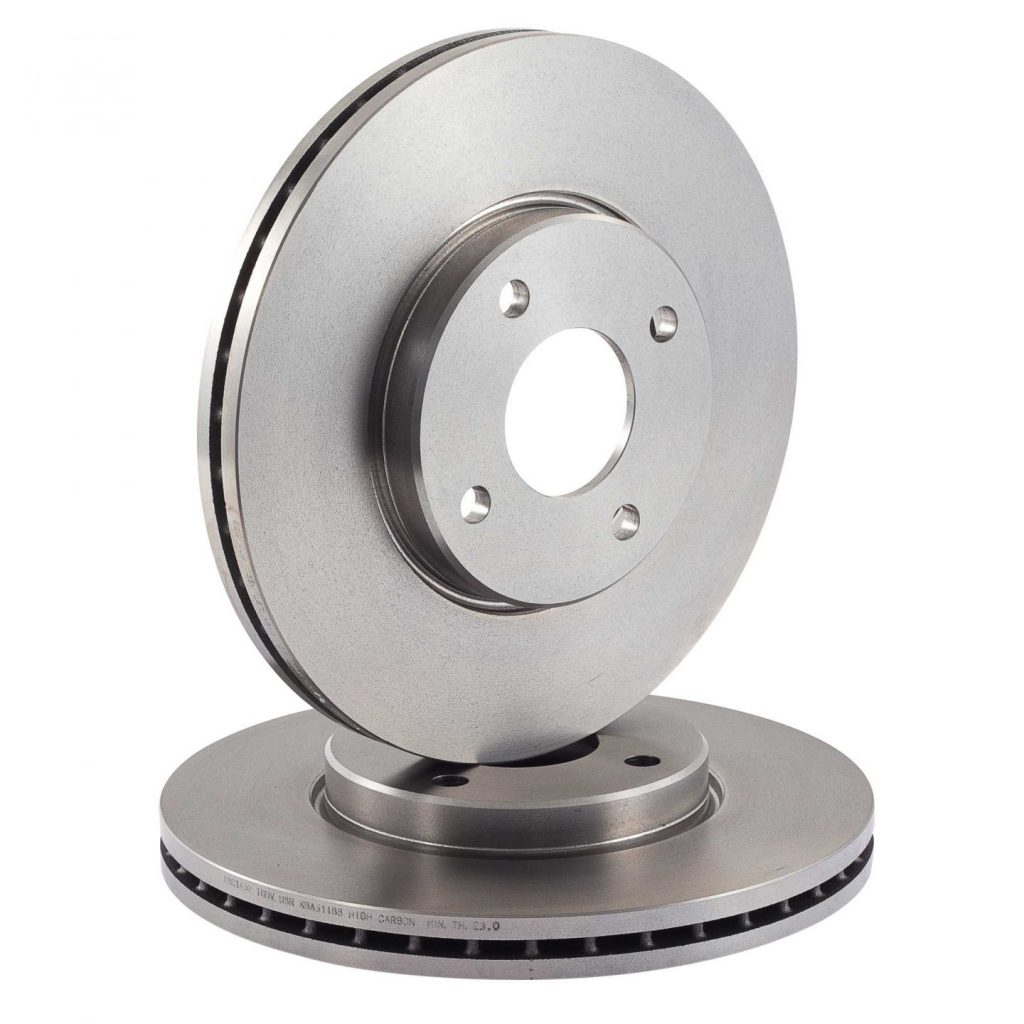

Discs

Discs are also an effective upgrade on their own, although generally for some of the more exciting looking options, we’d probably recommend matching them to a harder compound which won’t just dissolve when used with a more aggressive faced disc.

Plain faced

Your original brake discs (unless you drive something very sporty) are probably plain faced. Many modern cars have vented discs. Don’t confuse this with drilled discs or anything like that. This means that the disc is split down the middle inside and has air vents. These are designed to allow heat out as you use the brakes.

There’s nothing particularly wrong with these discs for normal driving. A well made plain faced disc will offer moderate pad wear and does work with pad upgrades. They don’t do anything to help with heat fade though.

Drilled

This would be where drilled discs come in. Drilled brake discs feature holes drilled through the face of the disc. This has a number of upsides and a couple of downsides. Firstly, it looks cool. We’re not going to deny it. Secondly, the holes allow more heat to escape. In the same way as the holes in the edge of a ventilated disc allow heat to escape and cold air in, these allow even more of both. The holes give increased bite. Under sustained braking, gas can build up between the pad and disc, which these holes allow to escape.

They do have some downsides for road use. The biggest in our opinion is that over time the surface of the disc can crack with heat. These cracks typically run between the holes. This can turn this type of disc into an MOT fail sooner than other types of disc. We’d also note that they tend to be noisy, and rough on brake pads if you’re not running the right sort of compound.

Grooved and Slotted Brake Discs

A good compromise for road use is discs with grooves or slots in the face. These are trenches along the surface of the disc. Unlike drilled discs, they don’t go all the way through.

This means you keep some of the benefits of a drilled disc, but without the worries about cracking.

A grooved disc can actually improve pad wear over time too, with the grooved pattern helping keep more of the disc in contact with the pad as it wears.

Grooves and slots work much the same, but slots tend to be shorter.

Brake Fluid

Fluid is an often-overlooked part of the braking equation. Your brake fluid is vital to making the rest of your set-up work though and choosing the wrong fluid or not changing it often enough can render the rest of your set-up much less effective.

There are two main differences with brake fluids.

Firstly – what kind of brake system they will work with. There are two main types of fluid. Glycol and Silicone based. Some cars do not like Silicone based. Others can use either, but you must clear the system out before switching.

DOT 3, 4 and 5.1 are all Glycol based. The different standards offer different boiling and freezing points. Most of the performance fluids we sell only meet DOT4, because while they greatly exceed the boiling point standards for DOT 5.1, they do not meet the viscosity requirements at -40 degrees C. This is probably not a major concern in the UK, or other warm/temperate climates. If you do live somewhere subject to extreme low temperatures, you might need to consider a 5.1 fluid.

DOT 5 on the other hand is Silicone based. We’d suggest checking carefully whether it’s going to be suitable for your specific vehicle. It may not work properly with ABS systems designed for Glycol based fluids.

Secondly – what temperature the fluid works up to. An uprated brake fluid will typically offer a higher boiling point than OE spec brake fluid. The minimum standard for DOT 5.1 fluid is 270 degrees dry boiling point, but some of the performance fluids available can offer dry boiling points of over 320 degrees C.

Even if you aren’t upgrading, it’s still worth giving your brake fluid some thought. Brake fluid has a boiling point much higher than that of water. That means the more water brake fluid absorbs, the lower it boils, and the less effective it is. Recommendations about how often vary, but it’s probably worth getting it checked every two years or so.

Braided Brake Lines

Once you’ve upgraded everything else, this still leaves your brake lines. These transmit the force of you pushing the brake pedal to the rest of the brake system. Any flex in the brake hose gives that force somewhere to go other than your brake calipers, and diminishes the effectiveness of your brakes. Brake hoses aren’t designed to flex when new, but the materials used can wear with age and start to balloon, particularly under pressure.

Upgraded brake hoses come with stainless steel braided outers that brace the outside of the hose and stop the brake lines flexing or expanding.

Big Brake Kits

While you can achieve great things with the right upgrades to the brake system your vehicle came with, eventually you can exceed what even an uprated pad/disc/fluid combo can do. Once you’ve reached that point, the only place left to go is bigger.

A Big Brake Kit (or BBK for short) is a matched set of uprated disc, pad, and either a new caliper or an adapter to allow you to use the existing caliper with a bigger disc.

By going bigger, you give the pad and disc more surface area to work with. An upgraded caliper will typically apply bigger pads over a much wider area. Normally this involves more pistons or pots. 4 is generally the minimum. This is two pistons on each side of the disc. Past a certain point, there’s nothing inherently better about more pistons.

Aftermarket calipers are designed to be very rigid and not to flex, so none of the force from the brake pedal goes astray between your foot and the brake pads. These are generally made of aluminium. Aluminium is lightweight and very rigid. We’ve seen both billet machined monobloc (one piece of aluminium) and two-piece calipers with high tensile steel bolts (very strong) used to good effect.

Obviously, and we cannot overstate this, big aftermarket calipers look really cool. A happy side effect of using aluminium is the ease with which it can be anodised. Red (or Green, if you like Skodas) brake calipers are a perennial favourite.

A bigger caliper allows you to accommodate bigger discs. These will generally use one of the performance face designs mentioned above. The discs may also be “floating”. This is where the business end of the brake disc is mounted onto the central hub using “bobbins”. These allow the disc to expand outwards as it heats up, without warping.

Pads are going to be a performance compound. Depending on the kit you may have a choice between a track compound and a road compound on the pads.

Some Big Brake Kits include rear pads as a matter of course. Where they do not, we’d probably recommend upgrading your rear brake pads at least.

Tyres

You might not consider tyres to be part of your brake system, but they are the only thing that connects your car to the road. Whatever other brake upgrades you apply to your car, if they overwhelm the amount of grip on offer from your tyres they’re then not doing you any good.

A tyre that is slipping is offering less stopping power, so fitting a huge BBK on tyres not up to the job can actually give you worse stopping power overall.

We’d say that if you need upgraded brakes then you also really need good tyres.