A typical race or rally car has many fasteners that aren’t found on the average production car. Many of these designs have come from the aircraft industry where reliable quick release fittings are invaluable.

Dzus fasteners are probably the most well-known example. There are many options available where two components need to be removed quickly for fast, easy access or replacement. We cover all the options below and show some of the typical applications.

Dzus Fasteners

The Dzus fastener was developed by Volodymyr Dzhus, originally from Eastern Galicia who emigrated to the US. He later took the name William Dzus. The fastener was developed in the 1930s to secure aircraft panels that needed to be quickly removed for access and maintenance. The Patent was filed in 1931 and the Dzus fastener soon came to motorsport after the Second World War, with returning serviceman who had seen their use on aircraft realising that the easy to use Dzus would work well on race cars and hot rods.

The Dzus fastener design consists of a spring-loaded stud encapsulated in a diamond-shaped plate riveted in place on the outer panel. The spring-loaded stud is compressed to reach through to the receptacle spring riveted to the inner panel/bracket. The stud is then rotated through a quarter turn which locks the stud to the spring (hence the common name quarter-turn fastener). This fastens the two panels together and is very resistant to vibration and accidental release, but can very quickly be released with a screwdriver, Dzus tool, or even a coin.

Dzus EHF5 Fastener

Dzus S5 Attachment Spring

Pitking Products 1/4 Turn Fastner

Pitking Products Reinforcement Plate

Pitking Products Weld-On Fastener Bracket

There are two common sizes of Dzus, the most common of which is the EHF5 type which is 37mm across the diamond-head end to end and 27mm between the rivet holes. The larger variant is the EHF6 and this measures 44mm from end to end and the rivet spacing is 34mm. This is much less common than the smaller version and an estimated 90% of applications use the EHF5.

If replacing an existing Dzus, the size of the plate and rivet spacing is the easiest way to determine which is required. The depth can be determined by measuring the stud from the head to the top of the slot where the spring rests. If selecting a Dzus fastener for the first time, the easiest way is to select by the grip length/material depth. This is the thickness of the two parts being held together. For example, two 2.5mm thick alloy panels would need a grip length/material depth of 5mm.

The attachment springs are available in different depths and sizes. The EHF5 Dzus will require the S5 spring and the EHF6 needs the S6 spring. The default size in the S5 spring is the S5-300 which gives 0.300” clearance but three other clearances are available. The S6 spring default size is the S6-400 which gives a 0.400” clearance, two other depths are available.

The grip length and clearance can be fine-tuned with an adjuster tool if the correct clamping depth is not achievable. The Pitking Products brand offers a black fastener that is interchangeable with the above Dzus fasteners and are ideal for classic applications etc. The 37mm version is the same size as the EHF5 and the 44mm as the EHF6. Black rivets to suit are available to complete the look.

Reinforcing backplates are available for all the above if use is intended on very lightweight panels. These spread the load and are especially useful on fibreglass, and there are mounting brackets for the springs available which can save a lot of fabrication work.

Dzus also offer the Panex range that works on the same design principle but does not have the top diamond shape encapsulated plate and instead sits directly on the panel to be secured. To calculate the length of stud required, add together the thicknesses of the panels being fastened, then add 7mm for the receptacle. Round up or down to the nearest mm to obtain the length required.

The head of the Panex can be slotted for a screwdriver or a D ring for manual opening. The head is retained by a spring washer fitted on the reverse side of the panel, these are available in steel or plastic. The receptacle can be either rivet type for mid panel use or slide on for the edge of panels.

Dzus Panex D Ring Fastener

Dzus Panex Rivet Receptacle

Dzus Panex Retaining Washer

Dzus Panex Slip-On Receptacle

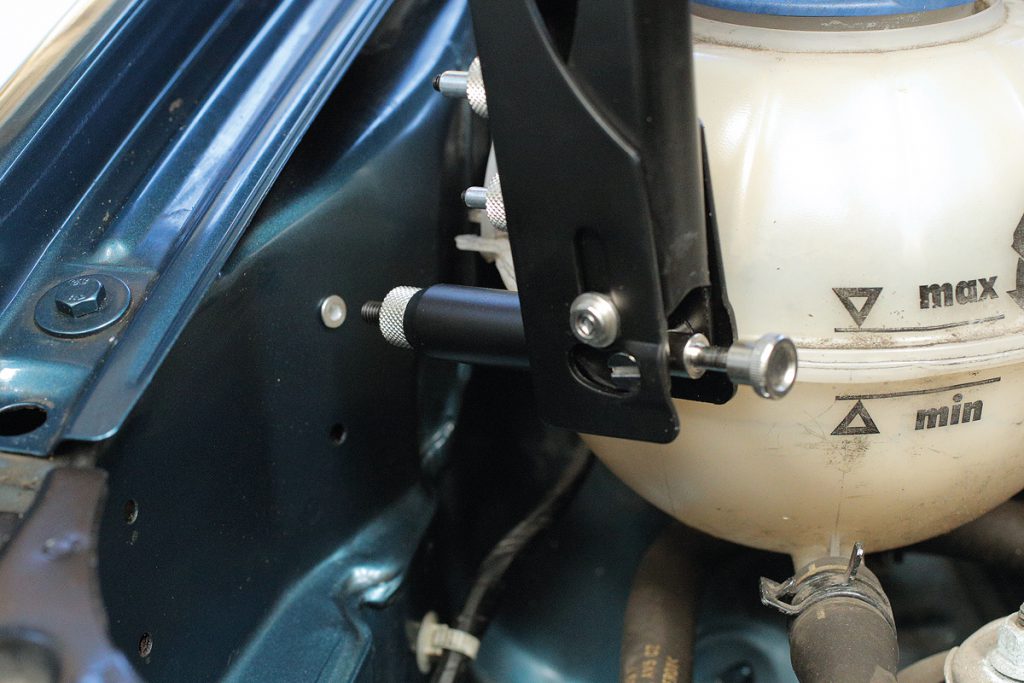

Camloc Fasteners

Camloc offers a range of quarter-turn fasteners very similar to the above Dzus Panex. The most popular type is the 2600 series that are available as a slot head or cross head. The 15F series is a push-button version that needs no tools to operate and is simply operated by a finger or thumb. All variants have a round flange to fit against the outside panel and are secured in place by a retainer washer.

The receptacle on the 2600 series is offered as a rivet on or screw on type and is held in place by a locknut. The 15F receptacles are screw on type only. The 2600 fasteners are selected by the combined panel thickness exactly as choosing a Dzus fastener. These start at 0.76mm and go up to 8.37mm, ten increments are available. The 15F series is only available to suit 0.7mm to 2.33mm depths.

Camloc 2600 Series Cross Head

Camloc 15F Series Push Button Type

Camloc 2600 Series Receptables

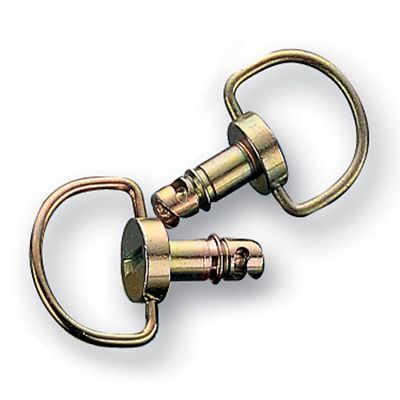

Pip Pins

Pip Pins are a quick release fastener released by a push button. The top panel is held in place by the shoulder on the Pip Pin and the lower part is held in a tube that matches the outer diameter of the pin shank. The Pip Pin has two spring-loaded balls near the end of the pin. These protrude once the button is released and hold the pin in place by protruding from the end of the tube the pin sits in.

The thickness of the panel and the depth of the locating tube combine to give the grip length required. A typical application would be to replace bonnet hinges with a pip pin to allow quick removal, single seaters sometimes use them on the anti-roll bar stay to allow easy engine access.

The Allstar brand offers a variation of the Pip Pin that has a T-handle that works in the same manner. This is easier to remove but the head is bulkier.

Pip Pin

Allstar Quick Release T-Handle Pin

Detent Ring Pins

Speciality Fasteners Detent Ring Pins are similar to Pip Pins but have no shoulder, just the ring to bear on the top panel. The spring-loaded balls allow quick and easy fitting and removal. The pin fits inside a tube in the same manner as a Pip Pin. The grip length is measured from the base of the ring to the ball retainers.

Dzus Slide Latch

The Dzus slide latch is intended to allow a panel to be quickly removed from the lower panel by a simple movement of the slide. The plate fits to the outer panel and is rivetted in place. The bush is fixed to the lower panel. The outer panel is secured by dropping the fastener over the bush and then sliding the tab over the bush. A typical application would be to hold a lamp pod or scoop on a bonnet.

Over Centre Latches

An over centre latch will pull two panels together and will lock in place by the tension caused by the offset of the latch. These can be adjustable for reach or fixed and sometimes have a positive secondary lock for extra security or alternatively a loop for padlock or lockwire. A typical fitment would be to hold a boot lid down against a rear panel.

Protex Adjustable Latch

Speciality Fastners Secondary Lock Latch

Grayson Lockable Overcentre Clip

Protex Catchbolt

Dzus Over Centre Clip

Aerocatch offers a recessed version that drastically reduces drag as pictured below:

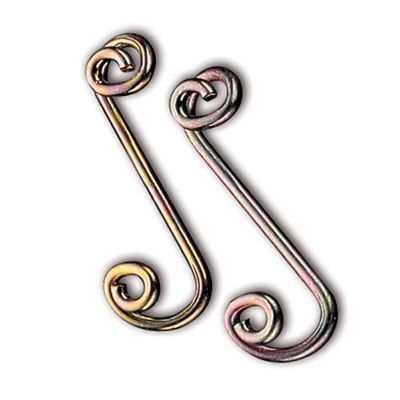

Spring Hooks

Spring hooks hold two panels together in a similar manner to overcentre clips but rely on the spring tension rather than the over centre action. Often known as boot springs as holding the boot lid or tailgate closed is the most common use. Sometimes known as Terry springs.

Rubber Hooks

The rubber hooks work in the same manner as the spring version, but the tension is provided by rubber. Popular in classic applications. The small version is often used on the original Mini to hold the bonnet shut.

Leather Bonnet Straps

The first motorsport fasteners came from horse saddlery and form a simple method of holding two panels together, leather bonnet straps are popular for holding bonnets in place on vintage and classic cars.

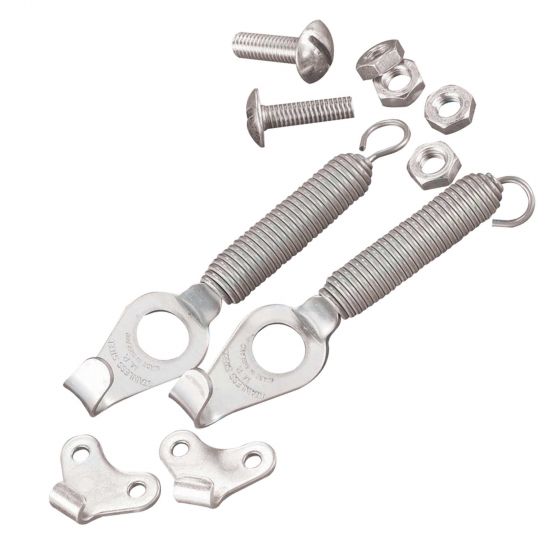

Bonnet Pins

Bonnet pins have a threaded pin with a hole at the top that fits into the lower panel or bracket and is held in place by two nuts. The pin then protrudes through a cut hole in the outer panel. The second part of the assembly then passes through the bonnet pin to prevent opening. This can be an R-clip on a wire or an over centre latch pin in a sliding channel. Recess plates can be used to fit to drop the top of the pin below the bonnet line.

Demon Tweeks Steel Bonnet Pins

OMP Aluminium Bonnet Pin Kit

Demon Tweeks Recessed Bonnet Pin Plates

A recent refinement is the flush button-operated bonnet pin. This is much nicer in appearance and more aerodynamic.

The search for clean flow aerodynamic bonnet pins also introduced Aerocatch to the market. These are bonnet pins with an open/closing cover instead of a simple plate, this reduces drag considerably and looks great at the same time. They are available lockable or non-lockable. They can fit over a pre-cut hole or from underneath and then moulded in.

Anchor Plates

Anchor plates encapsulate a nut and are rivetted to the lower panel and allow a bolt to screw in and pull down the top panel. They are available fixed or floating. The fixed is used on accurately spaced panels, floating where some misalignment needs to be allowed for.

Fixed Nut Anchor Plate

Floating Nut Anchor Plate

Riv-nuts

The rivet nut/riv nut/blind rivet nut is a one-piece internally threaded and tubular rivet that can be anchored entirely from one side. This leaves a threaded nut on the inner/lower panel. These blind rivets can be used on panels and flat face tubing. They can also be used on painted surfaces as no heat is involved, and they will not distort the surrounding area. An appropriate rivet tool is used for installation, these usually come with a selection of riv nuts. Riv nuts can be bought in assortment packs or individual thread packs. A typical use would be to mount components on a panel/bulkhead.

Rubber Nuts

The rubber nut is an insert that fits in the lower panel and deforms to be held in place when tightened. They are typically used where the upper panel needs to be isolated from vibration, an example would be mounting an ECU.

Cleco Clamps

The Cleco clamp came from the aircraft industry like many of the fasteners. Cleco’s differ in that they are temporary fasteners used to hold to components together during assembly/fabrication. The clamp fits into drilled holes and holds together with spring pressure. The spring pressure is normally compressed with Cleco pliers and this allows the Cleco clamp to pass through the workpiece. Releasing the spring load will cause the end piece to expand and grip the two workpieces together. Ideal if drilling a series of holes in a panel that need to align perfectly. Cleco Side clamps allow edges on panels to be held if holes are not required.

Cleco Clamp

Cleco Clamp Pliers

Cleco Side Clamp

Conventional Fixings

Bolts / Screws

The threaded bolt/screw probably needs no introduction but there can be a bewildering choice. The distinction between a bolt and a screw is commonly misunderstood. Bolts are for the assembly of two unthreaded components, with the aid of a nut. Screws, in contrast, are used in components that contain their own thread.

Bolts are often used to make a bolted joint. This is a combination of the nut applying an axial clamping force and the shank of the bolt acting as a dowel, holding the joint against sideways forces. For this reason, many bolts have a plain unthreaded shank (called the grip length) as this makes for a better, stronger dowel.

The heads can be hexagon type to take a socket or spanner, cap/Allen head to take hex key or Allen key. Materials can be high tensile steel, stainless steel, alloy, or titanium. Care must be taken to use the correct material for the intended application. Using alloy bolts to hold your brake calipers in place would be unsafe but their lightweight nature would be great for holding lightweight panels on for instance.

Nuts

Nuts are threaded to match the appropriate bolt. They are available in the same materials as above and care should be taken to match the intended use. Nuts rely on friction to hold together, but where vibration or circular movement is likely to be encountered locking versions are available. The Nyloc nut locks by a nylon insert that is a smaller diameter than the thread and grips the bolt thread. The motorsport/aerospace K-nut locks by having an elliptical offset part to the thread. Locking can also be provided by lockwire or locking washers. Locking washers can be serrated surface or spring washers that push against threaded surfaces.

Pop / Blind Rivets

Pop rivets will hold two panels together in low load applications. These are tubular rivets and are supplied with a mandrel through the centre. The rivet assembly is inserted into a hole drilled through the parts to be joined and a specially designed tool is used to draw the mandrel into the rivet. This expands the blind end of the rivet and then the mandrel snaps off. A tight joint formed by the rivet body remains.

Pop rivets can be inserted and fully installed in a joint from only one side of a part or structure, “blind” to the opposite side. Pop rivets can be installed with manual guns or air/drill operated if many are to be used or regularly. They can be used with above Cleco clamps to keep the correct alignment while the riveting is performed.

Helicoil / Thread Repair

The Helicoil kit while not really classed as a fastener can be used to repair or strengthen an existing fixing. If a thread is damaged, the helicoil kit will have a tap to allow the component to be tapped to take the helicoil insert. This takes it back to the original thread size. If the insert is fitted to a soft metal component the increased diameter of the outside of the insert adds strength to the joint, and the added benefit of being less likely to suffer thread stripping.

A guide to motorsport fasteners can never be exhaustive but the above should cover the basic types and how to select them. It will also help to determine the best option for your intended application. If you are new to a build it is often a good idea to visit a motorsport venue and have a look in the pit area, take pictures and talking to competitors can pay dividends.

Internet image searches can also provide inspiration on the best fastener option (and sometimes show the wrong option, but this can point to a better solution!)

We hope you find useful, if you need more information please do not hesitate to contact us by phone, e-mail, Facebook or visit our showroom.