Temperature regulation is a vital part of motoring and motorsport, helping to keep the engine at a comfortable temperature so that it can work as hard as possible for as long as possible, this is where the car cooling systems come into place. A bit like a runner, it’s often easier to run at cooler temperatures than it is in the peak summer sun; and the same is true for your car, kart or motorcycle’s engine.

If you can keep the engine at a comfortable temperature then everything works more smoothly and efficiently, delivering the power where and when you need it and at the very heart of this regulation is the cooling system.

A crucial part of the whole engine, your cooling system is working from the moment you turn the key (or press the button, more commonly these days) until you switch off the engine and in this guide we’ll take a look at how the cooling system works, how to check it and how – and what – to upgrade to maximise its performance.

How does the cooling system work?

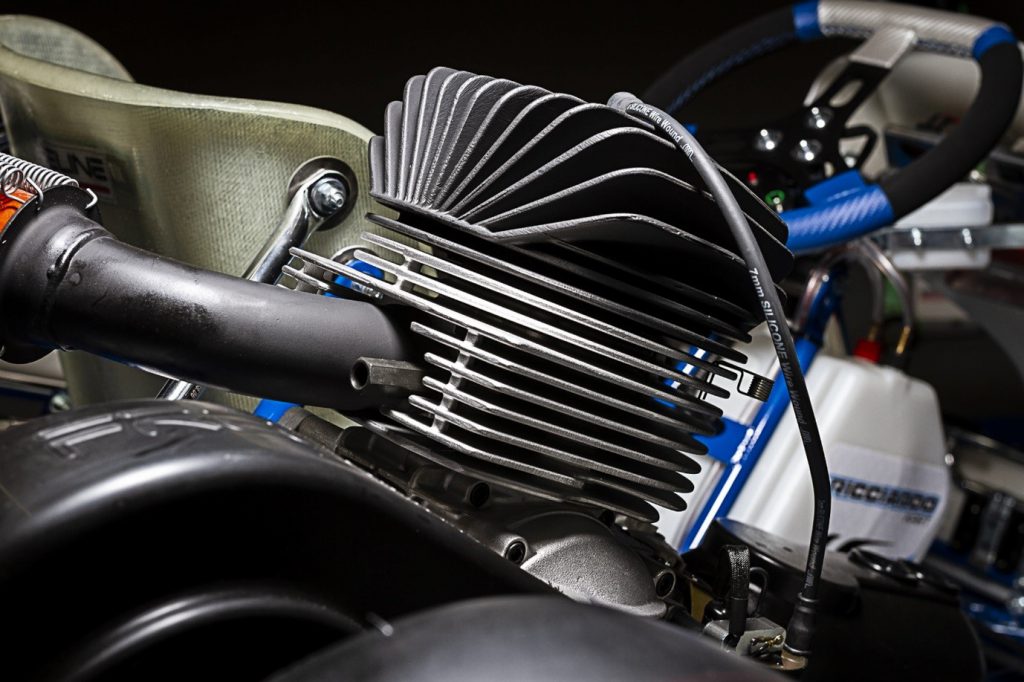

Engine cooling uses either air or liquid to remove the waste heat from an internal combustion engine. Air cooling takes fresh air from the atmosphere and makes for a lightweight, simple system and is used on some older cars such as the Porsche 911 and VW Beetle, as well as a number of motorcycles and karts. On water-cooled engines, excess heat is transferred from a closed loop of water pumped through the engine which is then cooled by a radiator.

Water has a higher heat capacity than air and can move heat more quickly away from the engine. Higher-power engines generate more waste heat, meaning they are generally water-cooled. The higher the state of tune, the more waste heat is created.

Cooling is needed because high temperatures damage engine materials and lubricants, with it becoming even more important in hot climates or motorsport conditions. Engines burn fuel at higher temperatures than the melting point of some engine materials, and hot enough to set fire to lubricants. Fortunately, modern engine cooling removes the heat quickly enough to keep temperatures down so the engine can survive.

Only the fixed parts of the engine, such as the block and head, are cooled directly by the main coolant system. Moving parts such as the pistons – and to a lesser extent the crank and rods – must rely on the lubrication oil as a coolant, or to a very limited amount of conduction into the block and hence the main coolant.

High performance engines frequently use oil sprayed upwards onto the bottom of the piston just for extra cooling. Air-cooled motorcycles often rely heavily on oil-cooling in addition to air-cooling of the cylinder barrels which explains why oil coolers are so common for motorsport applications.

Liquid-cooled engines usually have a circulation pump. The early engines relied on thermo-syphon cooling alone, where hot coolant left the top of the engine block and passed to the radiator where it was then cooled before returning to the bottom of the engine. This circulation was powered by convection alone but modern engines tend to have a pump driven by a belt.

Some manufacturers now use an electrically powered pump, which have the advantage of the output not being dictated by engine speed. This can also be controlled via the ECU to match other parameters.

Oil has about 90% of the density of water, so a given volume of oil can absorb only about 50% of the energy of the same volume of water. Despite this, if the cooling system (water or air) is at its limits an oil cooler can help bring the cooling back to an acceptable level.

How to check the car cooling system

The first step before upgrading the cooling is to check the original car cooling system is working to its full potential. The coolant should be to the correct level and replaced within the recommended service intervals. The condition of the radiator and cap should also be checked, while the cooling fins should be clear of dirt and debris. The area that feeds the radiator needs to be clear of obstructions like poorly placed lights, while grilles can actually cause more harm than good by affecting airflow quite badly. Fine mesh grilles can look great but can block a lot of airflow, so removing it or fitting bigger aperture mesh may be a solution.

The cooling fan needs to be checked for free rotation (disconnecting the battery or fan wiring beforehand makes this safer). Engine driven fans or viscous fans are best replaced with an electric fan for use in motorsport (as electric fans can run much faster at slower engines speeds.) The thermostatic switch for electric fans should be checked to ensure that it switches on the fan when required, and at the correct temperature.

The hoses should be inspected to make sure they are in good condition with no hardness, cracking or deterioration. Inspect all clamps and connections for proper fit and tightness; and both the fan belt and belt to the water pump need to be in good condition, free from cracks and tears to save future issues.

Air cooled engines should have the fins cleared of any dirt or debris and any metal ducting should be checked for good air flow and any holes that can reduce the air flow available. Many air-cooled engines run a factory fitted oil cooler, so the condition of the fins and hoses should be inspected, and a check made for good airflow.

How to upgrade the car cooling system

Having performed all your checks and ensured that the cooling system is in good condition you can start to think about how and where you can start making performance upgrades to maximise efficiency. Here we’ll talk you through a number of options that can all make pretty fast and smooth improvements to your car cooling system.

Coolant

Water is a great medium for removing heat, but it can be helped with the correct additives to increase heat transfer. Red Line offer the well-known Water Wetter, DEI offer Radiator Relief, Millers Extra Cool and Mishimoto Radiator Coolant Liquid Chill are also good options.

These break down the surface tension which will reduce or eliminate bubbles or vapour in the system around hot spots meaning the unwanted heat can be transferred directly to the coolant. This can be used with pure water in summer or mixed with Anti-Freeze in winter. If the system is being drained there is also the option of using ready to use coolant such as Redline Supercool Water Wetter or Motul Inugel Optimal Coolant.

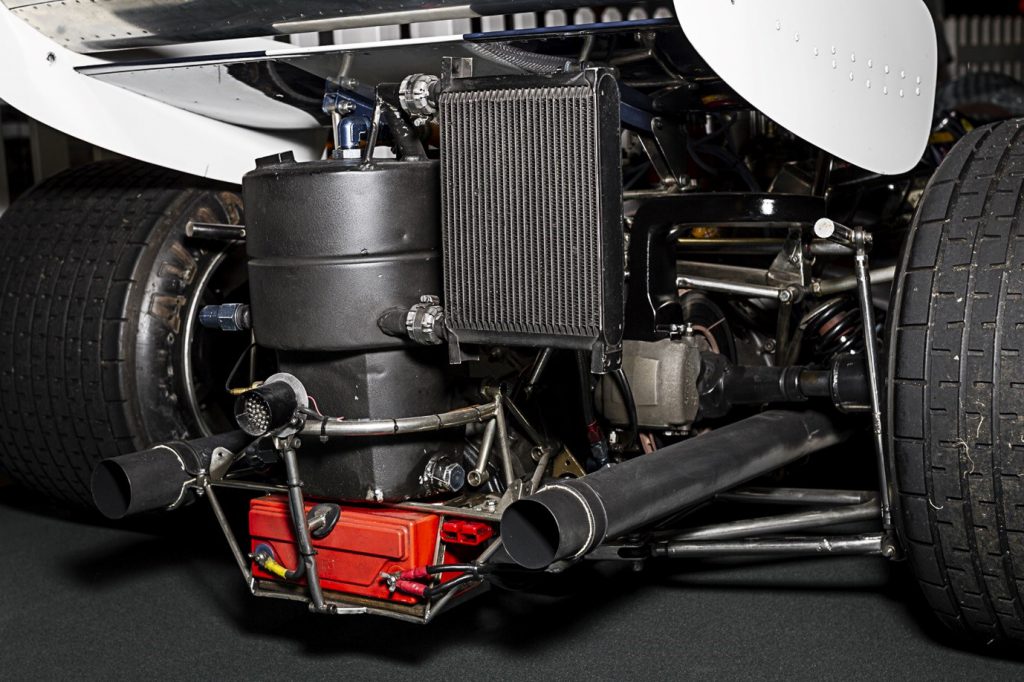

Radiator

The stock radiator is designed to give adequate cooling for the cars intended use with its construction and materials usually made with cost very much in mind. A quality aluminium radiator will have a far more efficient core, typically with more rows and often with a larger surface area. The ends caps / tanks will be welded to the core so will allow a higher system pressure (factory radiators often have plastic end caps crimped on). These are listed for many popular performance models.

We also list many universal radiators in a selection of sizes and shapes which is ideal if the car has a different engine to the original or if the engine has been relocated, or simply for cars not listed. Most radiators will have a port for an electric fan switch. The alloy construction may also give a weight saving advantage over standard, while also looking a lot more attractive than the original. In most applications, these radiators will hold more than the standard equivalent which increases the amount of coolant available to transfer the heat from the engine.

Radiator Caps

The factory fitted radiator cap is spring loaded and usually rated to around 15 psi. This allows the water boiling point to be above the normal 100 degrees Celsius at sea level. An uprated cap will allow for a higher boiling point than the standard version and we offer a choice of maximum pressures. If you are running a stock cooling system, care should be taken not to go too high as the increased pressure may find any weak links!

Caps are available in two sizes, a standard palm size cap and the smaller cap commonly found on Japanese cars and motorcycles. Some caps have a temperature gauge in the top for a quick visual under-bonnet check.

Cooling Fan

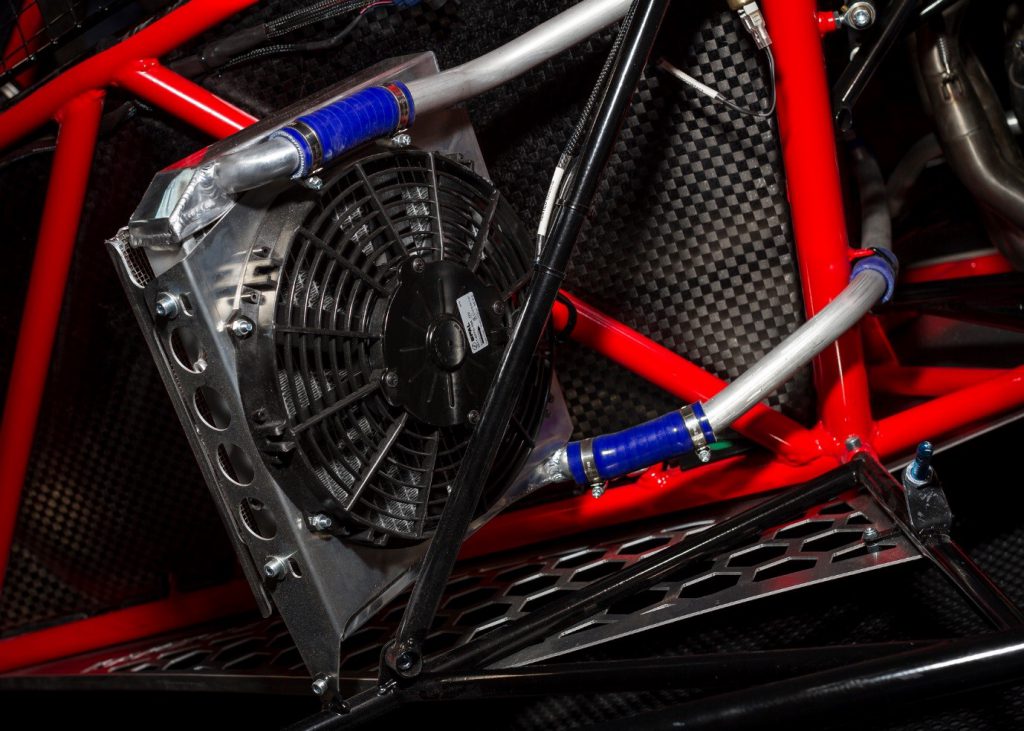

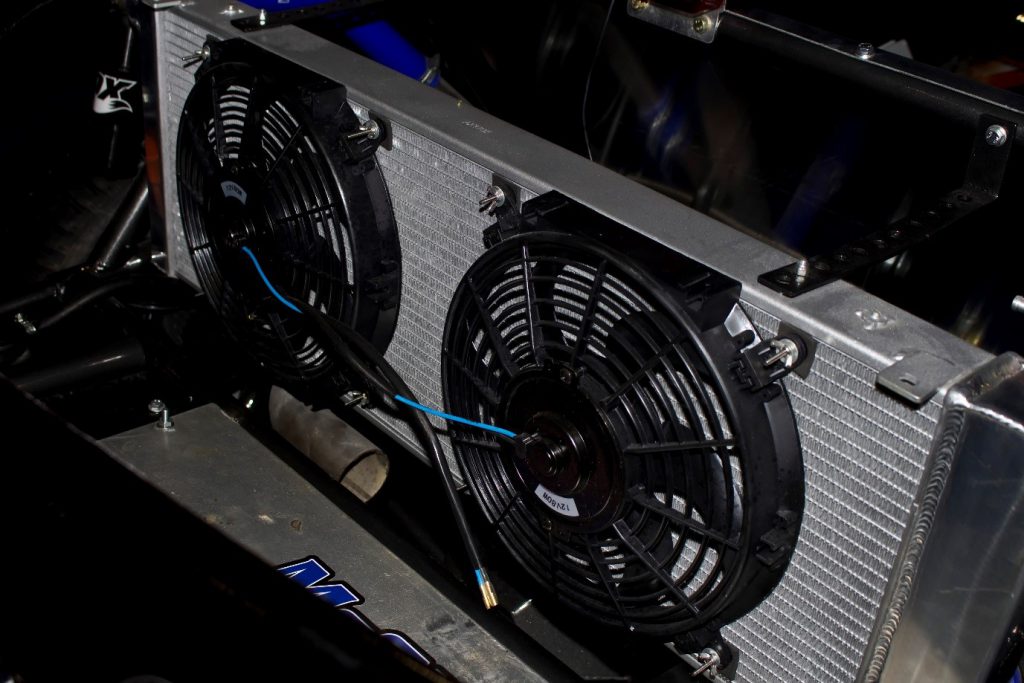

The cooling fan increases the airflow over the radiator to allow better cooling at slower speeds. The airflow at high speed will generally be enough, but motorsport cars are rarely at a constant speed. Factory fans are designed for the car’s original intended use, but in a motorsport environment the fan may not be efficient enough or cover the area of an upgraded radiator.

Cars with engine driven fans, viscous or fixed, are ideally replaced with an electric fan. The rotation speed of an electric fan is not determined by the engine speed, so can give full airflow even at tick over. Taking the engine driven fan off will also free up a little extra power as the engine is not having to rotate the fan when it is not needed.

The other advantage of an electric fan is that it can run when the engine is off and prevent damaging heat soak. Electric fans are available in many different diameters and depths and a general rule of thumb is the deeper the fan, the more powerful the motor, but the space available can often determine the choice.

Most of the fans are directional as this is more efficient than uni-directional. Blowing, also known as pushing, fans are placed in front of the radiator blowing air directly. Suction fans are placed behind the radiator, but in front of the engine.

A shallow but wide radiator can often accommodate two fans side by side. Fans can be mounted directly to the radiator with single use pull tie kits or can be fixed to the outside of the radiator shell using the brackets available. The fan is preferably switched by an electric fan controller (see below), factory fan switch, or via an on/off switch, but sometimes run all the time (wired via the ignition switch).

Fan Controllers

The factory fitted electric fan is normally controlled by a fan switch that will come on a pre-set temperature. An aftermarket fan controller can have the trigger point altered and can come on earlier (or later) than the factory unit. They can also be used on cars with no fan switch (i.e. if removing an engine driven fan) or to trigger a second fan.

The fan controller can also be bypassed by a switch if working in the engine bay or if off road wading. Fan controllers can be fitted inline in a suitable water hose, by cutting a short piece from the hose and refitting the hose ends over the hose stubs. They are also available in various threads to suit standard fan switch ports or other galleries on the engine. There is also an option for a sender to be fitted directly to a hose with a self-sealing take off, or a probe type that pops in the top hose and the hose refitted. Davies Craig offer a digital controller that can control the fan and an electric water pump if fitted. This gives a digital display of real time data and is the ultimate solution.

Water Pumps

An electric water pump can also be used to improve cooling while at the same time increasing power to the driven wheels. It can be used as an auxiliary pump in addition to the existing mechanical water pump to significantly improve cooling or as the main pump.

The EWP is wired through a thermal switch, often the same switch which operates electric radiator fans, with both the fans and EWP connected directly to the battery. In this set up, when the engine reaches the thermal switch setting both the fans and the EWP will turn on and cool the engine until it reduces to the switch off temperature.

When the engine is hot and idling, the mechanical pump will be moving coolant at about 15 litres per minute, while the EWP will kick in with up to an extra 150 litres per minute depending on the model, therefore dumping a huge amount of heat.

As they are wired to the battery, on hot shut down the fans and EWP will run together and take out heat, which will protect the head gasket, turbo and other components from excessive heat damage.

The mechanical water pump is one of the last mechanical components on a modern engine which is considered inefficient. Some newer cars are now being fitted with factory electric pumps.

A mechanical belt-driven water pump runs at the same speed as the engine regardless of how hot the engine is. For example, when travelling at high speeds the engine requires less cooling as ram air is cooling the engine, however, as the engine speed is high as is the mechanical water pump thus providing excessive cooling whilst draining the engine of power.

At slow speed when the engine is hot, and the engine is idling or slow, the mechanical pump will also be turning slowly, even though extra flow is required to cool the engine. A mechanical pump works very efficiently when it’s not required and very inefficiently when it is required!

The electric water pump corrects this inherent problem by delivering maximum cooling when it’s needed. A Davies Craig digital controller as mentioned in the last section, will connect the operation of the cooling fans and water pump for optimum cooling.

Oil Coolers

If the water-cooling system is optimised or the engine is air cooled, an oil cooler will help cool the engine and help the oil stay in grade. The cooler will also add to the volume of oil in the system. Ready to fit oil cooler kits are available for a lot of the most popular performance cars.

The cooler will normally take oil via a sandwich plate fitted in the standard oil filter location (the oil filter unscrews and the plate then fits between engine and filter hence the name sandwich plate). The oil cooler is normally mounted in the grill area to catch cooling air. The ready to fit kits will have hoses to suit.

Universal parts are available if the car is not common or if it has a non-standard layout. Oil coolers are available in the conventional oil to air type and air to water types. The air to water types are useful if there is no space to mount a conventional cooler, or where mounting in the normal position means it is very likely to damaged.

We can supply fittings and hoses to build your own bespoke system for both types of cooler along with thermostatic sandwich plates and inline thermostats if the car is likely to be used in cold weather.

Ducts & Ducting Hose

Airflow to the radiator is increasingly becoming smaller on aerodynamic modern cars, so sometimes extra ducts are required to feed cool air to the right areas. These are available in black for use in bumpers, headlight apertures and bonnets etcetera; and can be painted if required. They are also available in clear, ideal to use on Perspex or acrylic windows on mid-engined cars.

Ducts are usually bonded, riveted or screwed in place. Silicone ducting with internal wire reinforcement can take the air to the required area. Clamps, mounts, and collars are available to make a neat installation.

Silicone Hose

Conventional rubber hose tends to deteriorate on the inside and the outside and can fail with little warning. Hoses should be checked for hardness or any signs of cracking. Silicone, ready to fit, hose kits are available for most performance models, but universal hoses and alloy joiners can allow a kit to be made if not available or the car is heavily modified. Silicone hoses offer improved reliability, durability and aesthetics over rubber hoses.

Gauges & Warning Lights

Production car temperature gauges normally give an idea if the engine is hot or cold rather than a specific temperature. A good quality water temperature gauge will allow for accurate readings and proper monitoring. Some have warning lights if the temperature goes above a pre-set value, allowing the driver to concentrate on the track. Standalone warning lights kits are also available and these include the light and a sender unit. Before you decide on direction to go with your car its best to consult a Motorsport Gauge and Sender Fitting Guide.

Expansion Tanks / Swirl Pots

The expansion tank allows hot, expanded, coolant to come from the radiator without venting outside the system and loosing coolant. Most original equipment header tanks are plastic and become brittle with age and heat from the engine bay. An alloy header tank will look better and will be more reliable (as well as looking great).

These can be car specific or universal, and some have sight glasses for quick level checks. The caps can be screw type or radiator cap style. Swirl pots can be added to a system if the system is prone to trapping air in the system. The swirl pot as the name suggests rotates the water at speed and removes the trapped air at the top so that it can vent to the expansion tank.

Heat Insulation

Unwanted heat from exhaust manifolds and turbos can heat the engine bay considerably. Heat Insulation products such as exhaust or turbo wrap can drastically reduce this heat radiation, which allows the unwanted heat to disperse elsewhere and help in exhaust velocity.

Water hoses in high heat areas can also be protected by heat barriers. Vulnerable electric components can also be insulated in the same manner. These heat barriers reflect heat by their reflective surfaces and the backing layers insulate and protect, these are vital elements of heat management.

Thermometer / Pyrometers

Hand held infra-red pyrometers can allow hot spots to be pinpointed, when the bonnet opens normally it just feels hot everywhere. A laser pointer unit shows the heat of different areas and can also be used on the radiator to check for areas where cooling is poor, indicating a possible blockage.

In summary

There are many ways to reduce engine temperatures, the above should give plenty of ideas of how you could structure your car coolant system. Many can be used together. If you still have any questions or would like to ask advice, our sales team will happily give extra detail on the products covered.